WHAT IS A POWER ASCENDER?

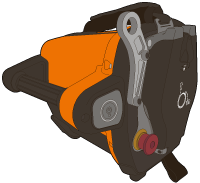

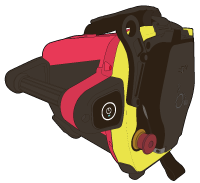

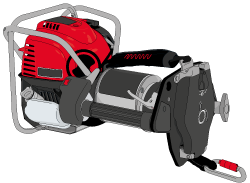

When ActSafe launched the first POWER ASCENDER in 1997, the rope access industry was revolutionised. Traditional manual climbing methods were replaced by a motorised climbing aid that provided fast and cost-effective access to work and rescue sites. A power ascender is a motorised rope winch that works like a personal hoist that travels up a standard rope. It is a versatile and robust tool that can be used in places where the use of a skylift, crane, scaffold or motorised platform is difficult or impossible. The ActSafe Power Ascender allows for quick assembly and disassembly, minimising disruption. Repair and maintenance can be carried out quickly, safely and cost-effectively.

Both the working rope on which the Power Ascender travels and a second backup rope are attached to a suitable anchor point. A light travelling fall arrester in accordance with EN 353-2 is attached to the backup rope, which in turn is connected to the front fall arrester eyelet of the harness used by means of a carabiner. In both cases, we recommend the semi-static ropes SUPER STATIC 11.0 or SUPER STATIC 11.0. Suitable seat harnesses in accordance with EN 813 are, for example, IGNITE ARGON, RECORD CACH oder RESCUE PRO 2.0 mit einem SKYBOARD.

However, most Power Ascenders can also be controlled by a second person on the ground to automatically raise or lower the person working with the device if they are no longer able to do so themselves.

WHAT NEEDS TO BE CONSIDERED WHEN USING A POWER ASCENDER?

Importance of the correct rope type and utilisation for safety when using the Power Ascender

Essential rope suitability test before each use

Recommended water soaking of ropes before use according to Instruction

Recommendation of the robust 11 mm static rope ELR for lifting loads

WHAT REQUIREMENTS MUST BE MET?

Users of ActSafe Power Ascenders must complete appropriate training. The motorised winches allow access to heights and depths in a very fast, safe and reliable way. They are very easy to implement in various working methods and are invaluable in places where access by other means is difficult or impossible. Due to the wide range of applications in different areas and circumstances, training is essential. Working at height or in hard-to-reach places requires a high level of dexterity that can only be achieved through comprehensive training and regular refresher courses.